I-5TH: Ukugcinwa kwesistimu ye-motor ne-circuit

I-motor kanye nesistimu yesifunda, engumthombo wamandla we-ukunitha umshini, kufanele ihlolwe ngokuqinile njalo ukuze kugwenywe ukuwohloka okungadingekile. Okulandelayo amaphuzu abalulekile omsebenzi:

1, Hlola umshini ukuvuza

2, Hlola ukuthi i-fuse ne-carbon brush ye-motor konakele yini (i-VS Motors nama-inverter motors ngaphandle kwe-carbon brush)

3、Hlola iswishi ukuthi ayisebenzi kahle yini

4,Hlola izintambo zokuguga nokunqamuka

5, Hlola injini, xhuma umugqa, hlanza ama-bearings (amabhodi) bese wengeza amafutha okugcoba.

6, Hlola amagiya afanele, amasondo ahambisanayo namabhande ebhande ohlelweni lokushayela, futhi uhlole umsindo ongajwayelekile, ukuxega noma ukuguga.

7, Yehlisa uhlelo: Hlola isisindo samafutha we-gearbox kanye ngenyanga, bese wengeza ngesibhamu sikawoyela.

Sebenzisa 2# MOBILUX amafutha okugcoba; noma SHELL ALVANIL 2# amafutha okugcoba; noma amafutha okugcoba e-WYNN anezinjongo eziningi. Noma bheka “Imanuwali Yemiyalo Yesistimu Yokugingqikela phansi Kwendwangu”.

6TH: Ukulungiswa, ukuqoshwa kanye nokufaka isivinini

1, Ijubane lokugijima leumshiniisethiwe, ibanjwe ngekhanda futhi ilawulwa yi-inverter

2, Ukuze wenze isilungiselelo, cindezela u-A ukuze uthuthukise idijithi eyodwa kanye no-V ukuze uhlehlise idijithi eyodwa,Cindezela > ukuze uhambise indawo eyodwa kwesokudla.Ngemuva kokuthi ukulungiselelwa kuqediwe, cindezela okuthi DATA ukuze urekhode, futhi umshini uzosebenza ngokuvumelana nesivinini sakho somyalelo.

3,Lapho umshiniiyasebenza, sicela ungacindezeli ngokungakhethi okhiye abahlukahlukene be-inverter.

4, Ukuze usebenzise futhi ulondoloze inverter, sicela ufunde "Inverter kanye Instruction Manual" ngokuningiliziwe.

7TH:Imbobo kawoyela

1, uhlobo lwenkungu oiler auto

A, Xhuma indawo yokukhipha umoya ye-compressor yomoya endaweni yokungenisa umoya yesijojo sikaphethiloli esizenzakalelayo ngeshubhu lepulasitiki, bese wengeza uwoyela yenaliti ethangini likawoyela ozenzakalelayo.

B, Lungisa i-compressor yomoya nokunikezwa kukawoyela, isisindo sikawoyela kufanele sibe sikhulu uma umshini usemusha, ukuze ungangcolisi indwangu.

C, Faka zonke izingxenye zeshubhu kawoyela ngokuqinile, futhi lapho uqala umshini, ungabona ukugeleza kwamafutha epayipi, okungukuthi, kuvamile.

D, Susa indle njalo kusihlungi somoya.

2, i-elekthronikhi ye-auto oiler

A, I-voltage yokusebenza ye-electronic auto oiler yi-AC 220±20V, 50MHZ.

B、^ Khetha ukhiye wesikhathi bese ucindezela kanye ukuze unyuse uhlaka olulodwa.

C. >Inkinobho yokuhambisa imbobo kawoyela, cindezela kanye ukuze uhambise igridi eyodwa, ihlukaniswe ngamaqembu amane e-ABCD.

3, SET/RLW Ukhiye wokusebenza wokusetha, cindezela lo khiye lapho usetha kabusha, bese ucindezela lo khiye lapho ukusetha kuqediwe.

4, Zonke izinkinobho zokusetha zisethelwe ukucindezela le nkinobho ngesikhathi esisodwa

5, Isinqamuleli se-AU Cindezela lo khiye ukuze wengeze uwoyela ngokushesha.

8TH:Isango lomshini

1. Elinye lamasango amathathuumshiniiyasuswa ukuze kugingqelwe indwangu, futhi isango kufanele liboshwe ngaphambi kokuthi umshini usebenze.

2, Isango eligudlukayo lifakwe inzwa emisa isango ngokushesha lapho livulwa.

9TH:Isitshina senaliti

1, Umtshina Wenaliti uzogxuma uphume ngokushesha lapho inaliti yokunitha iphuka, futhi izowudlulisela ngokushesha ohlelweni lokulawula, futhi umshini uzoyeka ukusebenza phakathi nemizuzwana engu-0.5.

2, Uma Inaliti iphuka, umtshina Wenaliti ukhipha ukukhanya kokukhanya.

3, Ngemva kokufaka inaliti entsha, sicela ucindezele isinqamu senaliti ukuze uyisethe kabusha.

10TH:Idivayisi yokugcina intambo

1, Idivayisi yokugcina intambo idlala indima enhle ekondleni intamboumshini.

2, Uma uhlamvu oluthile luphuka, ukukhanya okubomvu kwensiza yokugcina intambo kuzokhanya futhi umshini uzoyeka ukusebenza ngokushesha phakathi kwamasekhondi angu-0.5.

3, Kukhona amadivaysi okugcina intambo ahlukene futhi angahlukaniseki. Idivayisi ehlukene yokugcina intambo ine-clutch, eshayelwa phezulu yi-pulley engaphezulu futhi ikhuphukele phansi yi-pulley engezansi. Lapho ubuyisela emuva intambo, qaphela ukuthi i-clutch ibambekile yini.

4, Uma i-lint itholakala ukuthi inqwabelana kudivayisi yokugcina intambo, kufanele ihlanzwe ngesikhathi.

11ST: Umqoqi we-radar uthuli

1, I-voltage esebenzayo yomqoqi we-radar uthuli yi-AC220V.

2, Umqoqi wothuli we-radar uzozungeza nomshini kuzo zonke izinhlangothi ukuze asuse ilinti lapho umshini uqalwa, futhi uzoyeka ukujikeleza lapho umshini uyeka.

3, Umqoqi wothuli we-radar ngeke ujikeleze lapho inkinobho icindezelwa.

4, Kubantu abaqoqi uthuli lwe-radar, ibhokisi elihlehlayo elingaphezulu kwe-shaft emaphakathi lifakwe amabhulashi ekhabhoni, futhi uthuli olusebhokisini elihlehlayo kufanele luhlanzwe umuntu osebenza ngogesi njalo ngekota.

Isaziso:

Ukuqina kwebhande kufanele kulungiswe ngokuhambisana nobubanzi besondo lokuphakela intambo isikhathi ngasinye.

12TH:Isheke Lokusulwa

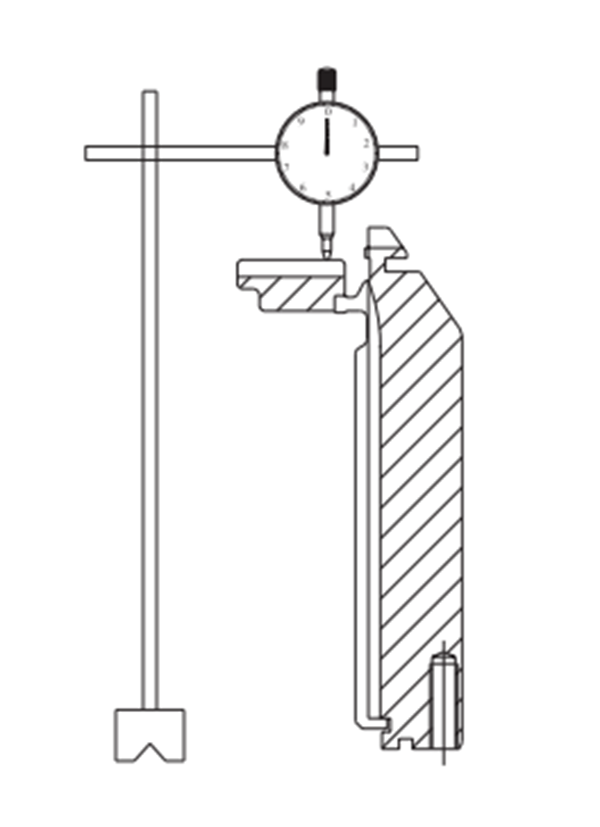

A, Sebenzisa igeji yokuzizwa ukuze uhlole igebe phakathi kwesilinda yenaliti kanye nonxantathu wendilinga engezansi. Ububanzi begebe buphakathi kuka-0.2mm-0.30mm.

B, Igebe phakathi kwesilinda yenaliti kanye nonxantathu wepuleti eliphezulu. Ububanzi begebe buphakathi kuka-0.2mm-0.30mm.

Ukushintsha amasinki:

Uma i-sinker idinga ukushintshwa, kuyakhethwa ukuthi i-sinker iphendulele endaweni yenotshi. Thuthukisa izikulufu, khipha i-upper plate cutout, bese ushintsha kuphela isinki esidala.

C. Ukushintshwa kwezinaliti:

Isikhundla phakathi kwe-latch yenaliti kanye nomtshina, indawo yomtshina kufanele ibe sesimweni esivamile futhi inaliti yokunitha ingadlula ngokushelela ngaphandle kokuma ngenxa yokuthinta umtshina.Ukukhethwa kwenaliti kanye nokufakwa kwayo kufanele kuqaphe kakhulu, ukuguqula umshini ngesandla endaweni yomlomo, bese ususa inaliti engalungile kusukela phansi bese uyibuyisela ngenaliti entsha.

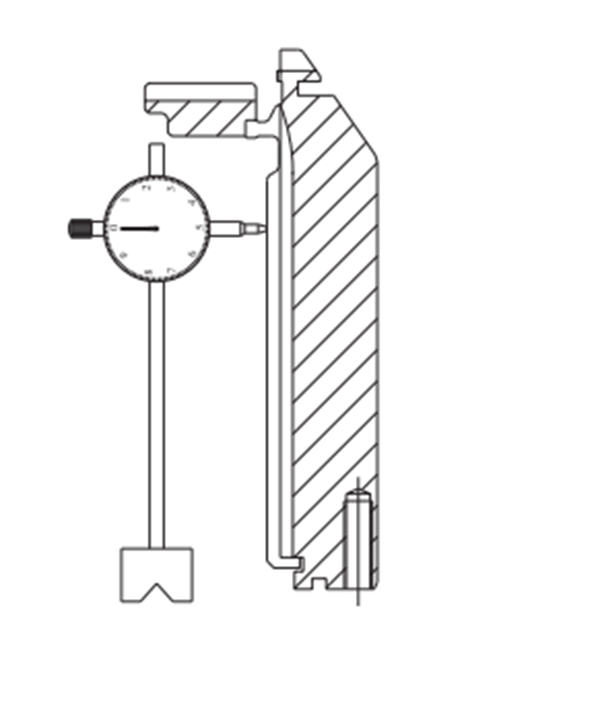

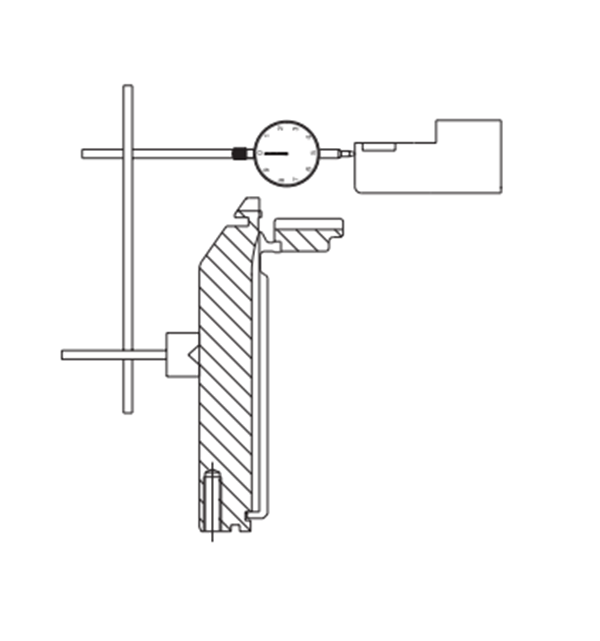

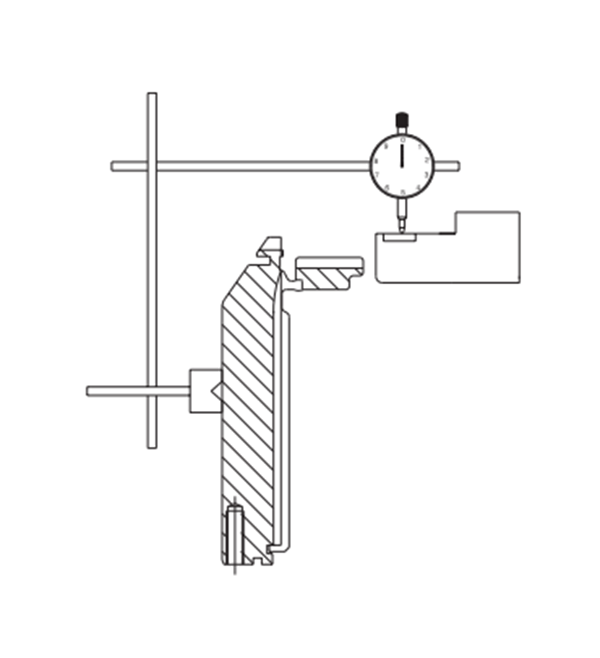

D, Ukulungiswa kokuma kwe-radial ye-sinker

I-sinker kufanele ilungiswe endaweni ye-P, bese inkomba yokudayela kufanele imiswe endaweni ye-O.

Khulula isikulufu A ukuze usunduze indawo yeradial kanxantathu wediski engenhla phambili noma emuva. Hlola ukuma kwe-siker ngegeji yokudayela.

E, Ukulungiswa kobude benaliti

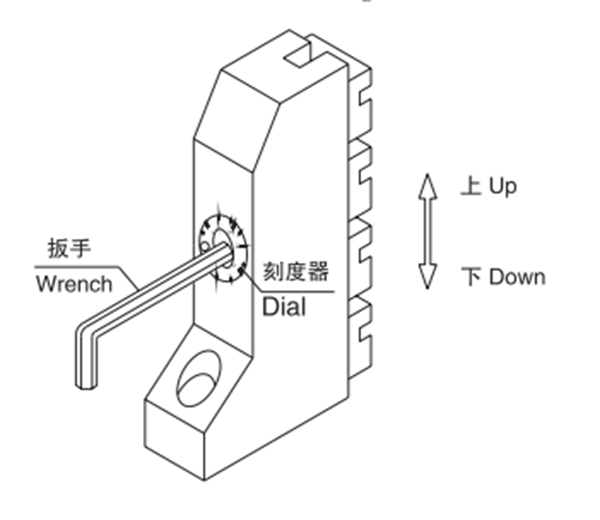

a, Sebenzisa i-6 mm Allen wrench ukulungisa isikali.

b, Lapho isikrufu sizungeza ngokwewashi, ukuphakama kwenaliti yokunitha kuncipha; lapho iphenduka ngokuphambene newashi, ukuphakama kwenaliti yokuluka kuyakhuphuka.

13RD:Izinga Lobuchwepheshe

Imikhiqizo yenkampani iye yahlolwa ngokuqinile, yalungiswa, futhi yahlolwa. Umshini oshisayo ongalayishi awukho ngaphansi kwamahora angama-48, futhi indwangu yephethini yokuluka enesivinini esikhulu ayikho ngaphansi kwamakati ayi-8. Ifayela ledatha lomshini selisunguliwe, futhi lingenziwa ngokuya ngezidingo zomsebenzisi.

1, i-cylinder concentricity (iyindilinga)

okujwayelekile≤0.05mm

2, I-cylinder Parallelism

okujwayelekile≤0.05mm

3. Ukufana kwepuleti eliphezulu

okujwayelekile≤0.05mm

5. I-coaxiality (iyindilinga) yepuleti eliphezulu

okujwayelekile≤0.05mm

14TH:Indlela yokuluka

Imishini yokuluka eyindilingaingahlukaniswa ngohlobo lwenaliti, inombolo yamasilinda, ukucushwa kwamasilinda nokunyakaza kwezinaliti.

Iumshini wokuluka oyindilingaikakhulukazi yakhiwe indlela yokuphakela intambo, indlela yokweluka, indlela yokudonsa kanye nendlela yokudlulisela. Umsebenzi womshini wokuphakela intambo uwukuqaqa intambo ebhobhothini bese iyisa endaweni yokuluka, ehlukaniswe yaba izinhlobo ezintathu: uhlobo olungalungile, uhlobo oluhle kanye nohlobo lokugcina. Ukuphakelwa kwentambo okungekuhle wukudonsa intambo ku-bobbin ngokucindezela bese uyithumela endaweni yokweluka elula ngesakhiwo futhi ukufana kokuphakela izintambo kubi. Ukuphakela intambo kahle ukuletha intambo endaweni yokuluka ngesivinini esingashintshi. Izinzuzo ukuphakela intambo efanayo kanye nokushintshashintsha okuncane kokuqina, okusiza ukuthuthukisa ikhwalithi yezindwangu eziphothiwe. Ukuphakelwa kwentambo yohlobo lwesitoreji ukukhulula intambo ukusuka ku-bobbin ukuya ebhobhoni yokugcina uhlamvu ngokuzungezisa ibhobhini yokugcina izintambo, futhi uhlamvu lukhishwa ku-bobbin yokugcina intambo ngokucindezela futhi lungene endaweni yokuluka. Njengoba intambo igcinwa kwi-bobbin yokugcina isikhathi esifushane sokuphumula, iyakhululwa ku-fixed-diameter yokugcina i-bobbin, ngakho-ke ingakwazi ukuqeda ukushuba kwentambo okubangelwa amandla ahlukene entambo ye-bobbin kanye namaphoyinti ahlukene wokuqaqa.

Umsebenzi womshini wokuluka uwukweluka intambo ibe yindwangu eyicylindrical ngomsebenzi womshini wokuluka. Iyunithi yemishini yokuluka engakwazi ukwenza ngokuzimela intambo ephakelwe ibe yiluphu ibizwa ngokuthi isistimu yokuluka, evame ukubizwa ngokuthi “Isiphakeli”. Imishini yokuluka eyindilinga ngokuvamile ifakwe ama-Feeders amaningi.

Indlela yokuluka ihlanganisa izinaliti zokuluka, iziqondiso zezintambo, osinki, amapuleti ensimbi acindezelayo, amasilinda namakhamera, njll. Izinaliti zokuluka zifakwa kumasilinda. Kunezinhlobo ezimbili ze-cylinder, i-rotary ne-fixed. Emshinini oyindilinga wenaliti ye-latch, lapho isilinda esizungezayo siletha inaliti ye-latch ku-slot yesilinda kukhamera engaguquki, ikhamera iphusha i-butt yenaliti ukuze ihambise inaliti ye-latch futhi iluke intambo ibe yiluphu. Le ndlela iyasiza ekwandiseni isivinini semoto futhi isetshenziswa kakhulu. Uma isilinda silungisiwe, inaliti yelatshi iphushwa ikhamera izungeza isilinda ukuze yakhe iluphu. Le ndlela ilungele ukushintsha indawo yekhamera ngesikhathi sokusebenza, kodwa isivinini semoto sihamba kancane. Inaliti izungeza nesilinda, kanti usinki ushayela intambo, ukuze intambo kanye nenaliti zenze ukunyakaza okuhlobene ukwenza iluphu.

15TH:Ukulungiswa Kwediski Ye-Aluminum Yokuphakela Izintambo

Ukulungiswa okuncane: Lapho ulungisa ububanzi besondo lokuphakela intambo, khulula nati elibophayo phezulu kwediski ye-aluminium.

Qaphela ukuthi uma isembozo esiphezulu sijikeleza, kufanele sigcinwe sivundlile ngangokunokwenzeka, ngaphandle kwalokho ibhande lezinyo lizowela ngaphandle kwe-groove yesondo lokuphakela intambo.

Ngaphezu kwalokho, ngenkathi kulungiswa ububanzi besondo lokuphakela intambo, ukungezwani kwebhande lezinyo le-tension rack kufanele futhi kulungiswe. Ukulungiswa kokuqina kwebhande.

Uma ukushuba kwebhande lezinyo kuxega kakhulu, isondo lokuphakela intambo kanye nebhande lezinyo lizoshelela, ekugcineni kubangele ukuphuka kwentambo kanye nendwangu emoshayo.

Lungisa ukungezwani kwebhande kanje:

Izinyathelo zokulungisa: Khulula isikulufu sokubopha sohlaka lwe-tension, lungisa indawo yesondo lokudlulisela ukuze ushintshe ukushuba kwebhande lamazinyo.

Qaphela: Ngaso sonke isikhathi lapho ubukhulu besondo lokuphakela kwentambo bushintshwa, ukushuba kwebhande lezinyo kufanele kulungiswe ngokufanele.

16TH: Uhlelo lokwehlisa indwangu

Umsebenzi wokwehlisa indwangu ukusebenzisa ipheya yamarola azungezayo adonsayo ukuze ubambe indwangu empunga, udwebe indwangu esanda kwakhiwa endaweni eyenza iluphu, bese uyisonga ibe uhlobo oluthile lwephakheji. Ngokwemodi yokuzungezisa yerola edonsayo, indlela yokwehlisa indwangu ihlukaniswe yaba izinhlobo ezimbili: uhlobo lwezikhawu kanye nohlobo oluqhubekayo. Ukwelula okuphakathi kuhlukaniswe Ukwelula Okuhle kanye Nokwelula Okubi. I-roller edonsayo izungeza nge-engeli ethile ngezikhathi ezithile. Uma inani lokuzungeza lingahlangene nokungezwani kwendwangu empunga, kubizwa ngokuthi ukwelula Okuhle, kuyilapho uma inani lokujikeleza livinjelwe ukungezwani kwendwangu empunga, kubizwa ngokuthi i-Negative stretching. Endleleni yokudonsa eqhubekayo, i-roller edonsayo ijikeleza ngesivinini esingaguquki, ngakho futhi idonsa kahle.

Kwezinyeumshini wokuluka oyindilinga, kufakwe nendlela yokukhetha inaliti ukuze kuthungwe umklamo nokuhlelwa kombala. Ulwazi lwephethini eklanyiwe lugcinwa ocingweni oluthile, bese izinaliti zokuluka zifakwa emsebenzini ngokwenqubo ethile ngomshini wokudlulisela.

Ukukhishwa kwethiyori komshini wokuluka oyindilinga ikakhulukazi kuncike ezintweni ezifana nesivinini, igeji, ububanzi, isiphakeli, imingcele yesakhiwo sendwangu kanye nokucoleka kwentambo, okungavezwa isici sokuphumayo=isivinini sesilinda (rev/ amaphuzu) × ububanzi besilinda (cm/2.54) × inombolo yesiphakeli. Umshini wokuluka oyindilinga unokuvumelana nezimo okukhulu ekucutshungulweni kwezintambo, futhi ungaluka imiklamo ehlukahlukene nemibala, futhi ungaluka izingcezu zengubo eziqedwe ingxenye eyodwa. Umshini unesakhiwo esilula, kulula ukusebenza, unomphumela ophezulu, futhi uhlala endaweni encane. Ithatha ingxenye enkulu emishinini yokuluka futhi isetshenziswa kabanzi ekukhiqizeni izingubo zangaphakathi nezangaphandle. Kodwa-ke, inani lezinaliti zokusebenza ku-cylinder alikwazi ukunyuswa noma ukwehliswa ukushintsha ububanzi bendwangu empunga, ukusetshenziswa kokusika kwendwangu empunga ye-cylindrical kukhulu kakhulu.

Isikhathi sokuthumela: Oct-23-2023