14-28 Intshi Mid Gauge Circular Knitting Machine

Izici

Ngobuhle obunobuntu kanye nobuhle obufanele bomklamo owenziwe lula, ukuphakama komshini wokuluka oyindilinga ophakathi kweGauge kulungele ukuthi opharetha enze umsebenzi kahle, sithe ukusebenza okulula. Kulula ukushintsha ama-Cams, Izinaliti nezinye izingxenye ngesiqondiso sethu sochwepheshe. Inzuzo yayo ukulondoloza isikhathi sephutha ukuze unikeze ukukhiqizwa okusebenzayo.

Ngesilinda esebenzisa i-aircraft ekhethekile ye-aluminium alloy material, isisindo esithe xaxa esilula silungele isivinini futhi yonga kahle isikhathi sokupholisa. Futhi ukubukeka komshini wokuluka oyindilinga we-Mid Gauge kungaphezu kwezinga eliphezulu

Ngomklamo okhethekile wohlelo lokuphakela intambo yohlobo olulengayo kuMshini Wokuluka oyindilinga we-Mid Gauge Circular Knitting, umhlahlandlela wentambo nokunamathiselwe kwe-Lycra kusesimweni esizinzile.Kusebenza kahle ukunikeza isivinini esikhulu sokukhiqizwa komshini nokugcina ikhwalithi enhle eqhubekayo yendwangu.

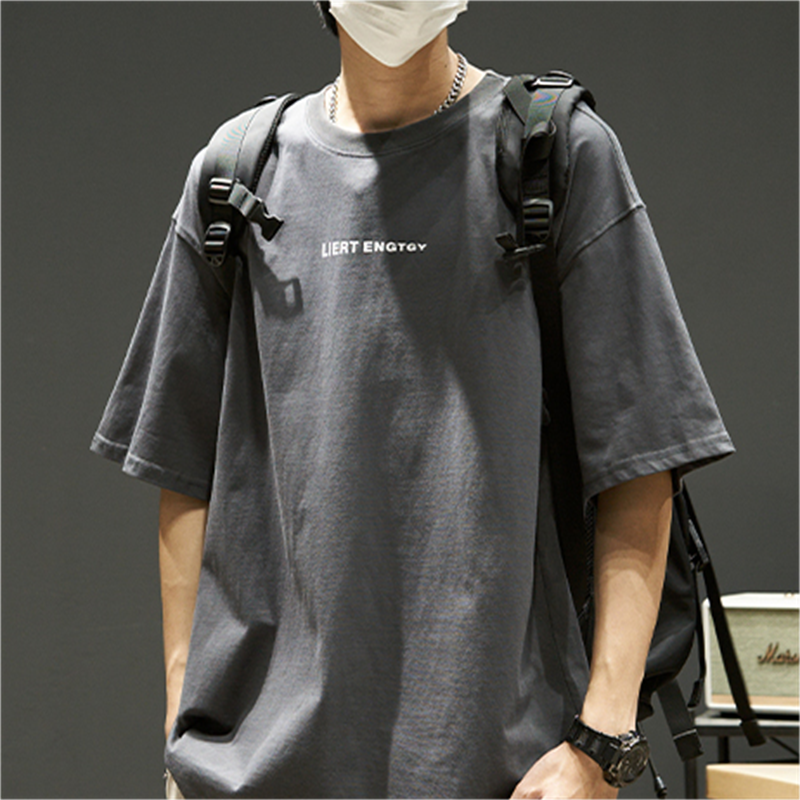

Isampula yendwangu

I-Mid Gauge Circular Knitting Machine izinto zokuluka ezisetshenziswa kakhulu intambo kakotini, i-polyester, i-TC, ngokushintsha ukuhlelwa kwamakhamera kungahlanganisa izicubu ezihlukene zejezi elilodwa noma indwangu yejezi eliphindwe kabili; Okufana nejezi elilodwa le-spandex, i-polyester / indwangu kakotini enoboya obubodwa, indwangu yombala, kodwa futhi ingakhiqiza indwangu eyodwa, enemeshi, njll.

IMINININGWANE

Kukhona ama-spindle amaningi ku-warp creel yomshini wokuluka oyindilinga we-Mid Gauge Circular Knitting. Ngokuhambisana nobubanzi bendwangu elukiwe kanye nobubanzi bentambo eyisicaba, kusetshenziswe inombolo ethile yezintambo eziqondile. Ngaphambi kokuba intambo ye-warp ingene eMid Gauge Circular Knitting Machine, intambo ye-warp iwela uhlaka olunsundu lwentambo ye-warp, futhi i-shuttle ye-warn ye-warn iwela Ekuvuleni, i-warp idluliswa ku-wap ngokunyakaza okuyindilinga, futhi ilukwe ibe yindwangu yeshubhu. Umshini Wokuluka Oyindilinga Oyindilinga ophakathi unama-shuttle amaningana, futhi imicu ye-weft eminingana ilukwa ngesikhathi esisodwa.

Ezinsukwini zakuqala, izinsimbi eziyisiyingi zasekhaya zonke zaziyizinsimbi eziyindilinga ezazingeniswa kwamanye amazwe, kodwa ngeminyaka yawo-1990, lesi simo sashintsha kancane kancane. Ngokokuqala ngqá, kwazalwa amaluki ayindilinga anamalungelo empahla engqondo azimele ezweni lami, kwathi ngo-1991, Ngo-1993 nango-1997, kwethulwa izindwangu eziyindilinga zesizukulwane sesibili, sesithathu nesesine ngokulandelana kwazo. Ngo-Agasti 2000, i-shuttle super circular loom yokuqala yomhlaba eyishuttle eyishumi, i-SPCL-10, yathuthukiswa ngempumelelo, yahlanganisa inani lobuchwepheshe obuthuthukile. /6000, isizukulwane sesihlanu esiyindilinga uhlaka lokweluka impahla, kwase kuthi ngoJanuwari 2005, uhlaka lokuqala lomhlaba oluyindilinga eyishuttle eyishumi nambili lwazalwa futhi lwalethwa kubasebenzisi. Eminyakeni emine kamuva, ngoNovemba 2009, kwa-odwa ipulastiki eyindilinga eyindilinga eyishuttle eyishumi nesithupha engu-SPCL-16/10000. Kuze kube manje, izinga le-Mid Gauge Circular Knitting Machine ezweni lami lihlale liklelisa ezingeni elihamba phambili emhlabeni.

1. Inzwa ye-Weft: Hlanza ikhava yomtshina njalo (kanye emahoreni amane). Uma Umshini Wokuluka Oyindilinga we-Mid Gauge usebenza, qiniseka ukuthi ukukhanya okumhlophe kuhlala kuvuliwe. Umtshina uklanywe ngokulandela isimiso semisebe ye-infrared. Ukukhanya okukhazimulayo kuzothinta ukusebenza kwenzwa. Zama ukuhlala eduze komshini ngangokunokwenzeka. Sebenzisa ama-bobbins asemini kuphela, uma ingaphezulu le-spindle licwebezela, umtshina ungase ungasebenzi kahle, gwema ukusebenzisa i-aluminium bobbins noma ama-black bobbins, intambo emnyama izokwenza umtshina ungasebenzi.

2. Inzwa yokuphuka kwe-Weft: Ekusebenzeni okuvamile kwe-loom eyindilinga, lapho intambo ye-weft iphukile ngenxa yamandla angaphandle, inzwa ibona isignali futhi iyidlulisele kumlawuli ukuze alawule i-loom eyindilinga ukuze ime. Uma intambo ye-weft iphukile, umshini awukwazi ukuma ngokuzenzakalelayo: Joyiza umshini, yenza ithubhu yokuqondisa intambo yeyodwa yamashuthi ihambe ngaphansi kwenzwa, ngesandla futhi uphule ngokushesha intambo ye-weft, ukuze ibhola lensimbi lingene ebangeni lokuthola lenzwa. Uma ukukhanya okunkomba okubomvu kwenzwa kungakhanyi, lungisa indawo yenzwa kuze kube yilapho ukukhanya kwenkomba ebomvu kukhanya. noma shintsha inzwa.

3. Inzwa eyinhloko yokuthola isivinini: Ngesikhathi sokusebenza okuvamile komshini wokuluka we-Mid Gauge Circular Knitting, uma ububanzi bemvamisa yokuguqulwa kwe-boost frequency bukhulu, kungenzeka ukuthi inzwa iphuthelwe ukutholwa kokujikeleza kwenjini eyinhloko ngenxa yokudlidliza. Ngalesi sikhathi, kuyadingeka ukulungisa isikhundla senzwa ukuze ikhanda lenzwa lihambisane nepuleti elinamazinyo. , bese ubheka ukwandisa imvamisa yokuguqulwa kwemvamisa. Uma ishaya phakathi kwebanga elincane, kwanele. Uma umphumela ungeke ufinyelelwe ngemva kokulungiswa okuningana, buyisela inzwa.

4. Phakamisa inzwa yokubona: Uma isixhumi esibonakalayo somshini womuntu singakwazi ukurekhoda ngokunembile okukhiphayo, hlola ukuthi izintambo zilungile yini. Uma i-wiring ilungile, lungisa ukuma kwenzwa, sebenzisa umshini, futhi ubheke ukuthi ukukhanya kwenkomba kuyaphazima yini. Uma ingabanizi, cabanga ukushintsha inzwa.Umshini Wokuluka Oyindilinga Omaphakathi